Résultat de recherche pour :

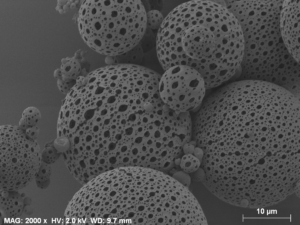

Encapsulation of Active Pharmaceutical Ingredient by Double Emulsion to Control Drug Release for Pulmonary Application

This application note deals with the encapsulation of an active pharmaceutical ingredient (API) in a biocompatible matrix to protect it and to control its release in time. We show that a right control of the formulation parameters allows to adapt the size and the porosity of the particles, the two mains characteristics which control and regulate the drug release kinetic. Double emulsion technology is used by GREEnMat to design these particles and to tailor their properties (size, porosity and percentage of the encapsulation).

Voir l'application noteFrom Suspension to Powder Using the Spray-Drying Process to Produce Kilograms of Powder as Anode Material for Li-ion Battery

The preparation of muticationic batteries materials as Li4Ti5O12 powder requires high homogeneity in the precursors to produce the powder with desired phase characterized with high electrochemical performances. This can be easily achieved with the spray-drying technology from nanoprecursor suspension. Using this fast process in a one step, we are able to produce at GREEnMat several kilograms of the desired material.

Determination of the Metal Content of a Pyrotechnic Aluminium Nanometric Powder: Study of the Effect of Powder History

In many domains (pharmaceutical, food industry, pyrotechnics materials …), the physico-chemical properties of powders impact hugely the quality of the final product. Normalized tests for granulomorphological and chemical characterizations of powders help to control their quality and the reproducibility batch to batch for limitation of the problems in production. Despite the use of standardized protocols, special care must be taken in the interpretation of the results because; unexpected phenomena related to the history of the powder can lead to poor conclusions. This application is focused on the metal content determination in a pyrotechnic nanopowders using thermogravimetric measurements and shows how results can be influenced by the powder history.

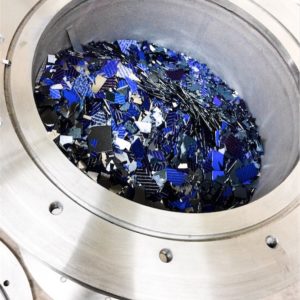

Undress your Waste to Give to its Components a Second Life with High Added Value: Solar Pannel Recycling

The societal, economic and environmental challenges of the beginning of the 21st century compel us to develop a sustainable consumption system such as that of the circular economy. In order to promote this business model, it is essential to promote the efficient use of resources, to improve the recyclability of materials, and to consider the life cycle of products placed on the market. In order to reduce the geopolitical tensions associated with the supply of raw materials as well as the environmental pressure linked to their extraction, it is necessary to consider the complex mixture of waste in the same way as ores. However, the complexity of the waste makes the extraction of materials of interest more difficult than that proceeded on the oressolar pannel desencapsulation-reenmat.

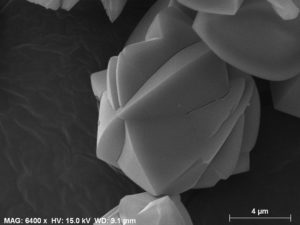

Hydrothermal Synthesis of Advanced and Controlled Powders

Hydrothermal processing is a non-conventional, one-step method to prepare crystalline inorganic materials with good morphological and surface control. It is a simple and effective way to reduce particle size and a suitable method for the morphological and surface control in one step. It consists in the precipitation reaction of chemicals in aqueous solution at moderate temperature and pressure, and is therefore very attractive for the preparation of particles in an environmentally friendly way. Phase formation in hydrothermal conditions often proceeds through one or several intermediates.

From micronic particles to milimetric granules using granulation process

A powder is a material composed of fine solid particles. These particles can vary in size and shape and generally consists of a wide particle size distribution that is inherent to the production mode employed and leads to a non-uniform final product.

The finer the particles are, the more hazardous they are and their manipulation requires the use of fumehoods and adequate personal protection equipment such as FFP2/FFP3 protection masks. This hazard also impacts the transport procedures from the manufacturer to the final user. So, one can be interested in reducing the volume of fine particles in the product.